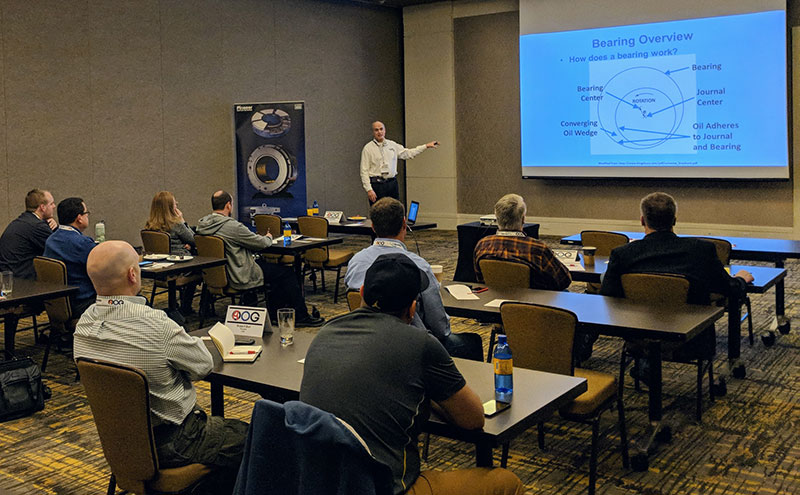

Fundamentals of Fluid Film Bearings

For maintenance, system and design engineers and technicians, we can provide a full gamut of the fundamentals of fluid-film bearings. Our initial focus on geometry, materials, and lubricants is the springboard to understanding critical issues for bearing installation and operation. We devote time to mechanisms and appearance of damage and consideration of alternative corrective approaches, as well as what careful inspection of bearing surfaces may reveal about machinery faults.

Customers can choose the entire 3-day course or selected issues from our syllabus. Mix and match content to suit your needs. And we’ll be happy to customize a seminar that addresses a customer’s specific critical issues or goals.

Advanced Topics

Though we routinely cover specific issues related to guide and thrust bearings, our attention in Advanced Topics is on the rotor-bearing system. The relationship between the bearings and control of the rotor’s position; system stability; balance forces; stiffness and damping; and vibration and cross-coupling effects are all included to shed light on the complex various causes of the rotordynamic characteristics and the vibration signatures of customers’ rotating equipment.

We can train at customer facilities or online. And we’ve done so for customers on four continents.

Engineering Education, Practical Experience and Leadership

Each member of our engineering team has advanced academic degrees concentrated on rotordynamics. Our team is led by Dr. Lyle Branagan, who after ten years of experience with Pacific Gas & Electric, the last five of which, armed with his doctorate, he served as a rotordynamics specialist, before joining Pioneer Motor Bearing in 1996.

Practical Experience

Because of Pioneer’s strong service and repair business in the electric utility aftermarket, our engineers have not been glued to computer stations but have had unsurpassed experience at hydroelectric, nuclear and fossil fuel power plants in North America, Central and South America, Western and Eastern Europe and New Zealand.

Subject Matter Experts

Our engineers serve as featured lead speakers at conferences of organizations such as:

- The Society of Tribologists and Lubrication Engineers (STLE);

- American Society of Mechanical Engineers (ASME); and

- The Electric Power Research Institute (EPRI), the “think tank” of the electric utility industry.

Our reputation extends beyond North America. In cooperation with France’s national electric utility, Electricite de France (EdF), the Institut Pprime routinely invites Pioneer to attend and speak at its bi-annual conference on bearings in Poitiers, France. In Australia, we have led the workshop on bearings at an EPRI Turbine-Generator User’s Group. We have provided training on rotordynamics and bearing theory at our plant in North Carolina to a group of engineers with the Korean Electric Power Company and for a prominent OEM of small hydro turbines at its plant in the Czech Republic. On short notice, we’ve provided engineering, technical service, and training classes to power plants in such places as Brazil, Sweden, Korea, Guatemala, and Slovenia.

For a description of lectures and published papers of Pioneer’s engineers, visit our Resources page: