We live and breathe large bearings for immense turbomachinery.

Some firms tout “engineering” but in reality offer only reverse engineering or pre-designed parts. Some have solid engineering but focus on small bearings. We at Pioneer have designed and manufactured bearings weighing as much as 10,000 pounds.

Our engineers hold advanced degrees in mechanical engineering – meet our technical team. They are focused on rotordynamics, and fluid film bearings and, provide our customers with non-biased professional engineering services to develop custom-engineered bearing solutions.

Our theoretical knowledge is enhanced and influenced by what we’ve observed over the decades in our manufacturing and repair departments. From our heritage of manufacturing large bearings for and designed by power generation OEMs, we’ve learned to seek “value engineering” opportunities in our own designs to reduce costs. And from what we’ve observed in our bearing repair operations, we’ve learned to incorporate into our solutions the best design features for performance and life extension while avoiding features that actually may contribute to bearing damage.

Our engineering and design work has been extensive. Examples include:

Airbus and Google-backed SpinLaunch

Pioneer was asked to design the critical hydrodynamic radial bearing for its 2nd-generation prototype Accelerator to launch missiles with small satellite payloads.

Knowing that hydrodynamic bearings have exceptional load capacity, our engineers rolled up their sleeves to exploit this shock load capacity for this truly challenging, unique radial bearing application.

In a vacuum, a 30-meter payload tether running at 450 rpm releases a payload of over 4,000 pounds of mass from the end of the tether at a speed 7 times the speed of sound. The radial bearing must sustain an instantaneous imbalance load for a half revolution. The shock was projected to cause strain on the armature and the rotor system. Based on our careful evaluation, approved by our customer, we designed and manufactured the bearing. We are proud of its successful performance through multiple, payload releases.

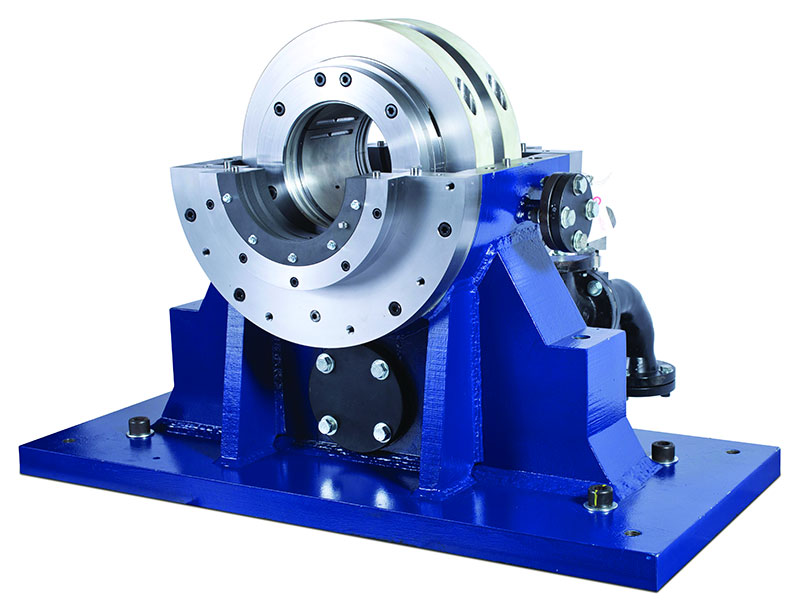

Custom Double Overhung Pelton Water Wheel Bearing Solution

We solved a 100-year-old problem with a custom designed and manufactured turn-key bearing solution.

New problems can arise when you demand more from your machine than it can handle. A 100-year-old double overhung Pelton hydroelectric unit suffered continuous bearing wipes due to extreme shaft bending and misalignment. Pioneer analyzed the issue and designed and manufactured an entirely new bearing system—a pair of 25” diameter pivoted journal/thrust bearings. Pioneer’s full solution upgrade now allows this hydroelectric unit to produce reliable clean power at its full potential.

General Electric Renewable Energy (Canada)

We designed and manufactured very large radial bearings for an immense synchronous condenser for General Electric Renewable Energy (Canada), for the Soldier’s Pond substation, part of Nalcor Energy’s massive Churchill Falls hydroelectric expansion project in Canada.

GE Hitachi Nuclear Energy (Wilmington, NC)

Pioneer provides GE Hitachi Nuclear Energy (Wilmington, NC) with both engineering design modifications and new bearings.

Pioneer’s work for GE in the nuclear industry stretches back to the era before GE in Wilmington existed, when GE nuclear had a substantial presence in San Jose, California.